Aluminium, at the heart of the fight against climate change

Use

Aluminium is used in a number of markets, including automotive, construction, electrical and electronics, and packaging. Its main characteristics (corrosion resistance, conductivity, lightness, recyclability) make it a material of choice from the perspective of using the right material in the right place.

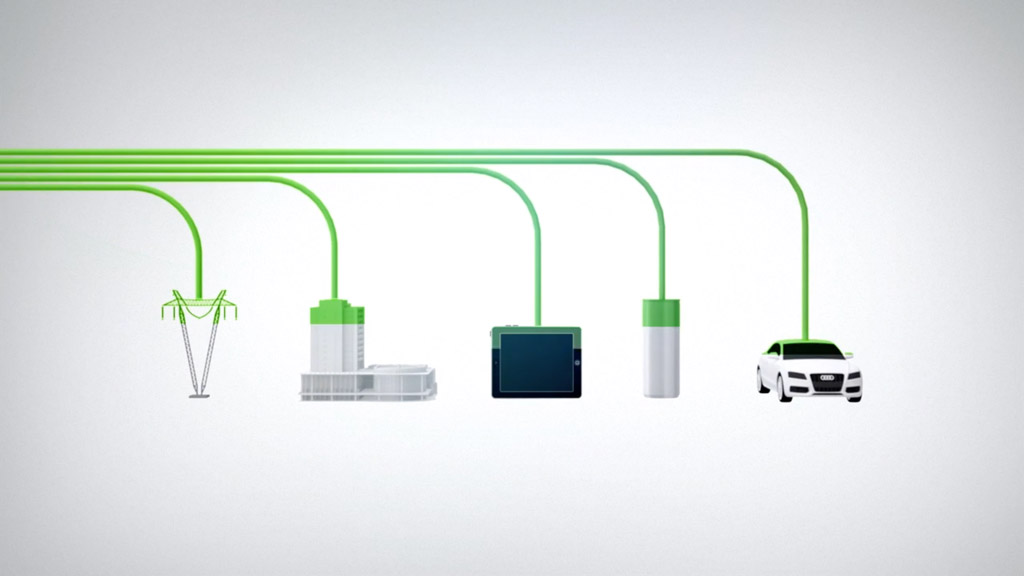

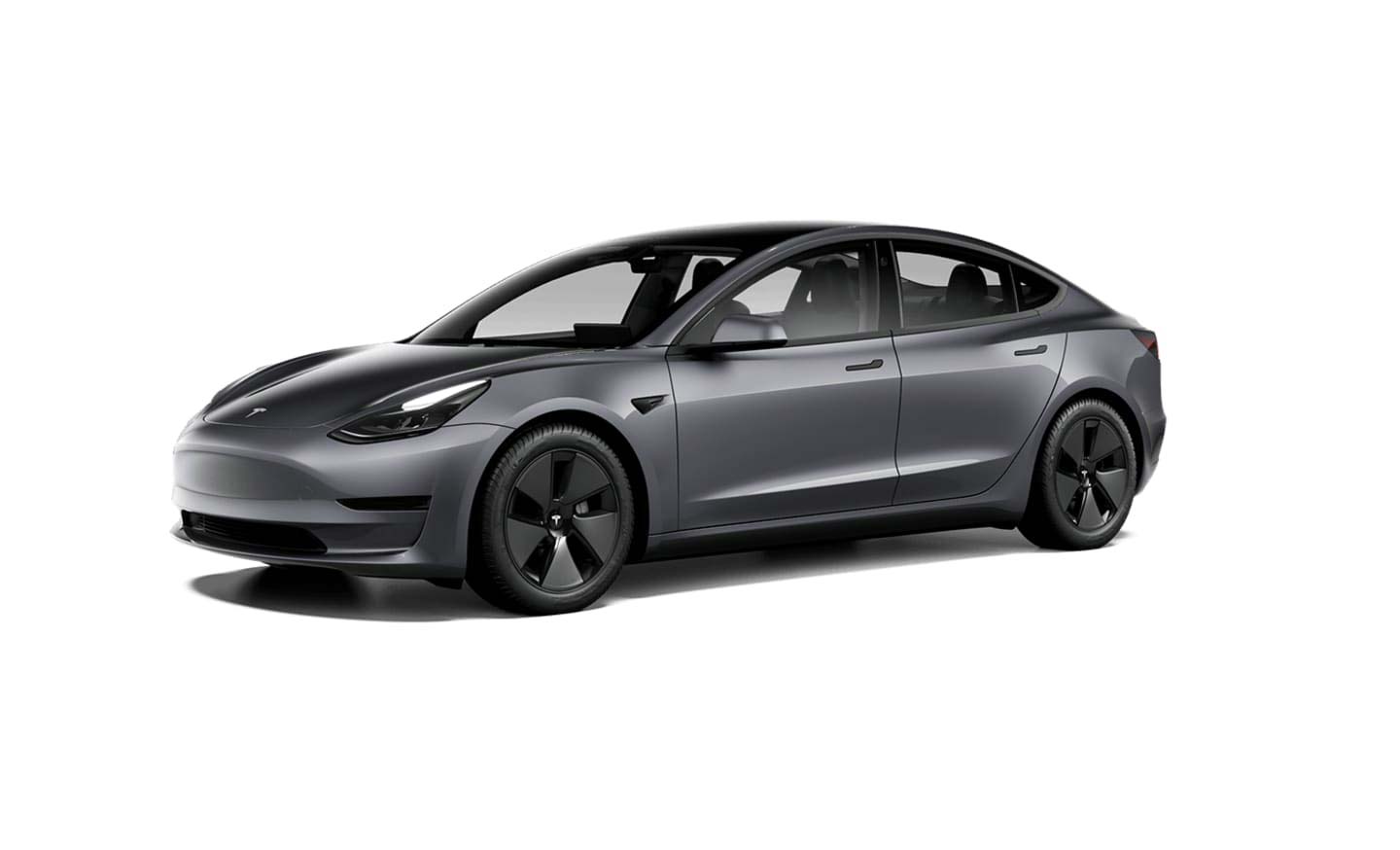

Aluminium is proving to be a solution to the fight against climate change, as it is increasingly used in the composition of certain levers for reducing GHG emissions (electric vehicles, batteries, charging stations, etc.).

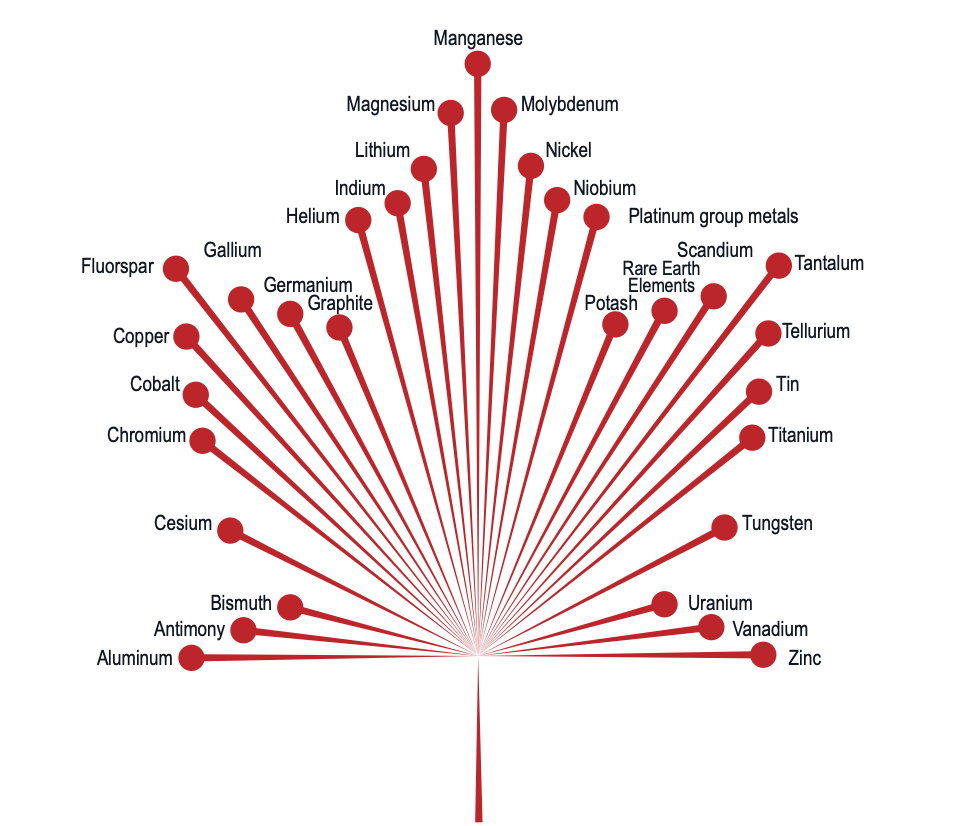

© Her Majesty the Queen in Right of Canada, represented by the Minister of Natural Resources, 2021

One of 31 critical minerals in Canada

Aluminium is part of Canada’s list of 31 critical minerals, recognized to be essential to Canada’s economic security, required for the transition to a low-carbon economy and a sustainable source of critical minerals for its partners.

Critical and strategic minerals in Québec

In Quebec, aluminium is recognized as one of the critical and strategic minerals. It is an essential mineral in our daily lives and the energy transition of the province, contributing to the decarbonization of the economy.

Production and products

It takes between four and five tons of bauxite to obtain about two tons of alumina which, in turn, will give one ton of aluminium.

Bauxite

Bauxite, containing a high aluminium content, is extracted from ore deposits, mostly located in tropical areas.

Alumina

Production begins with the refining of bauxite and its conversion through the Bayer chemical process to obtain alumina. The resulting product, aluminium oxide (Al2O3), is calcined resulting in a product known as calcined alumina which takes the form of a white powder.

Aluminium

Alumina is used as an input to the electrolytic process (Hall-Héroult process, named after its inventors) which is carried out in tanks through which a high-intensity direct current passes. The result is molten aluminium. Once the liquid metal is collected, it is transferred to a casting center, where it is purified, alloyed to customer specifications, and then cast into various forms.

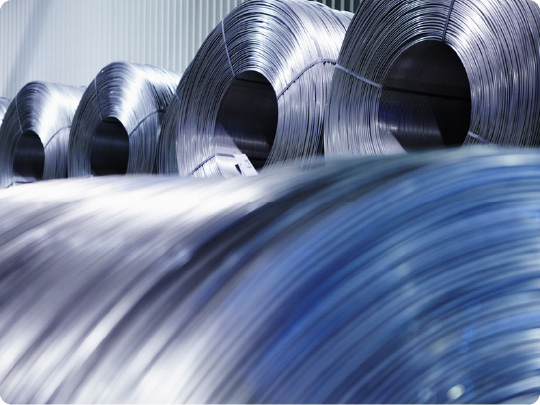

Main products stemming from primary aluminium production

Billets

Sows

T ingots

Plates

Rods

Aluminium and energy

Our relationship with energy is multi-dimensional. Our ongoing performance below the world average of 14,1 MWh of electric intensity per unit of production is very competitive. While being the most energy intensive industry, we are Hydro-Québec’s largest client.

Fortunately, all this renewable energy is not “consumed” because we transform 93% of it into aluminium through the electrolysis process. It is as much value generated from own electrons.

This makes the industrial sector a creator of wealth for Quebec, thus becoming the second largest exporter of energy in Quebec after Hydro-Québec.

Traceability

Our secured traceability platform allows the industry to certify the authenticity of the Canadian origin of the primary metal crossing the American border. Initiated in 2020, this project follows the conclusive results of two pilot projects carried out in 2019-2020.

Recycling

The incomparable recyclability of aluminium is part of its genetic code and is a determining factor in the environmental performance of this noble material. Its recycling only requires 5% of the energy required during its initial production. Aluminium does not lose any of its properties during recasting.

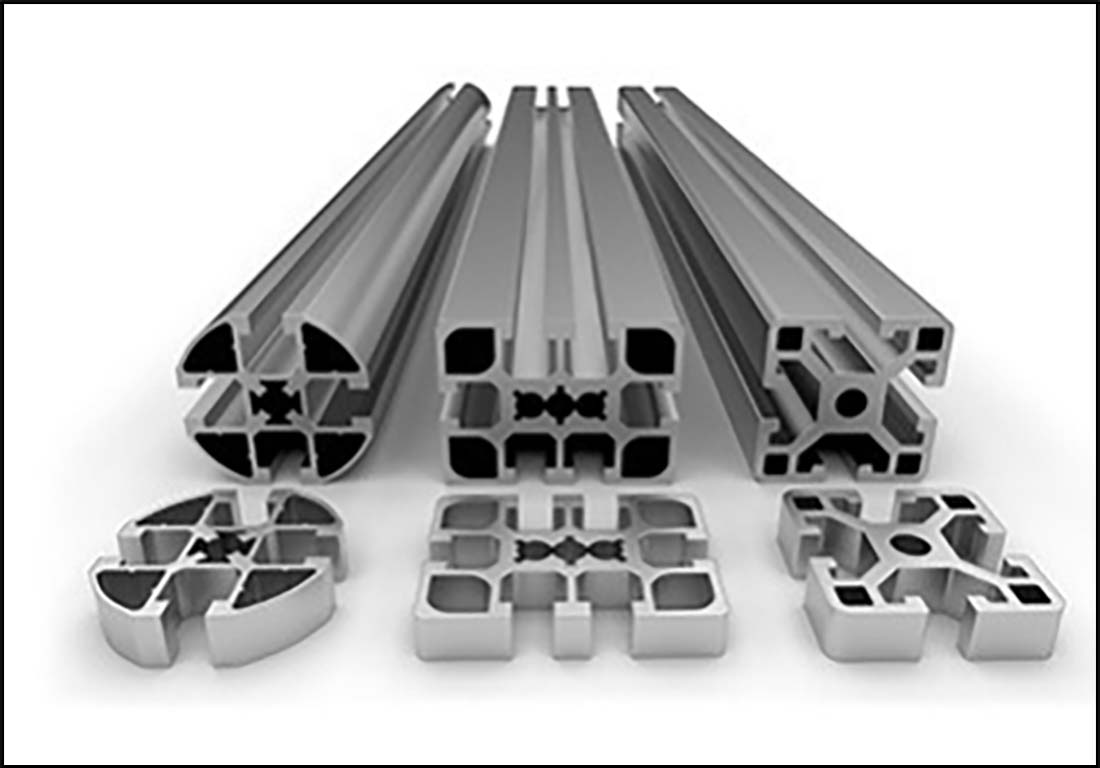

Processing

AluQuébec coordinates the Quebec aluminium processing industry and creates synergies between client-users and players in the Quebec aluminium ecosystem.