Over 100 years of history in Canada

Since its introduction in 1901, the aluminium industry has experienced phenomenal growth in Canada. Its history is intimately related to certain regions. The construction of aluminium smelters spurred the rapid social and economic development of the Centre-du-Québec, Saguenay–Lac-Saint-Jean and the North Shore in Quebec, as well as the Kitimat region in British Columbia.

1901

Birth of the industry in Quebec

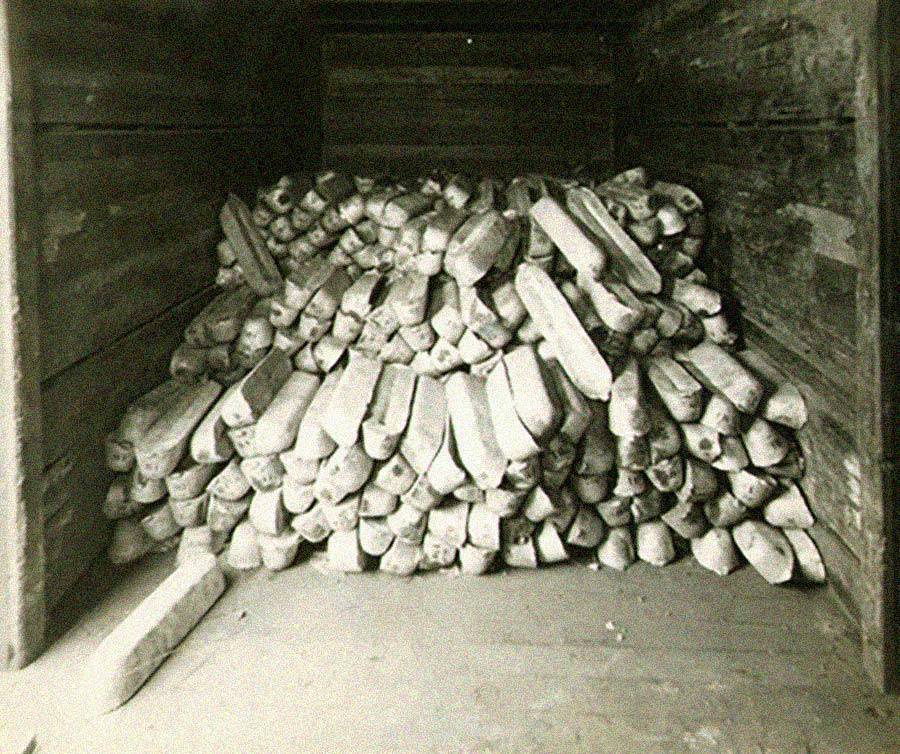

In Canada, the aluminium industry first located in Quebec, close to the Shawinigan Falls on the Saint-Maurice River. The Pittsburgh Reduction Company, later renamed Alcoa, poured its first ingot of aluminium in Quebec on October 22, 1901.

The electrolysis process used to manufacture aluminium requires a great deal of electric power. This is why the industry chose to concentrate its activities in Quebec, with its many waterways.

The First World War played a significant role in the prodigious growth of the aluminium industry. From 1914 to 1918, world production almost doubled, from 69,000 to 131,000 metric tonnes.

1925

Building of the world’s greatest aluminium complex

In the spring of 1925, the Northern Aluminum Company started construction of the Arvida aluminium smelter. On July 8, 1925, the Northern Aluminum Company Limited was renamed the Aluminum Company of Canada.

One year later, on July 27, 1926, the first cells in the Arvida plant began to produce aluminium.

1925-1945

Growth of the Aluminium Company of Canada, Alcan’s predecessor

Support to the war effort: The Second World War was instrumental in the exceptional growth of the aluminium industry, with world production tripling between 1939 and 1943, going from 687,000 to 2,200,000 metric tonnes.

1945

Founding of Alcan

In March 1944, Quebec’s aluminium smelters attained their maximum production during the war years, 1,400 metric tonnes per day. In the years following the end of World War II, demand for aluminium dropped due to wartime overproduction; however, recovery was quick in coming.

Demand surged once again. Between 1946 and 1952, world production almost tripled, growing from 774,000 to 2,032,000 metric tonnes. Aluminium was increasingly being used for civil purposes, particularly in manufacturing airplanes and automobiles as well as various domestic products.

Another producer arrives: In 1955, a second aluminium producer gained a foothold in Quebec: the Canadian British Aluminium Company, which subsequently became the Canadian Reynolds Metal Company. The company began with the secondary fabrication of aluminium, acquiring a share in an aluminium plate rolling mill at Cap-de-la-Madeleine. Two years later, it undertook construction of a plant in Baie-Comeau on Quebec’s North Shore.

During the 1960s, Reynolds established other plants in Quebec. In 1981, it launched a major expansion and upgrading program for its Baie-Comeau smelter. In 1985 and in 1991, it added two series of potlines to its facilities, increasing its production capacity to over 400,000 metric tonnes a year.

Between 1977 and 1988, Alcan constructed new aluminium smelters in La Baie and Chicoutimi, known as the Grande-Baie and Laterrière smelters. In 1980, Alcan inaugurated a secondary metal plant in Guelph, Ontario.

1951

First aluminium smelter in British Columbia

In 1951, across the Queen Charlotte islands, at the mouth of the Kitimat river, Alcan initiated a $500 million project, the largest public-private partnership ever introduced in Canada at the time. An aluminium smelter in Kitimat, which started up production in 1954.

1986-1997

Three new smelter projects in Quebec

Bécancour

Starting in 1986, three new aluminium companies located in Quebec.

Aluminerie de Bécancour, a joint initiative of Pechiney (France), la Société générale de financement du Québec (SGF) and Alumax (U.S.), started production in 1986. At the time, this was the largest private investment ever carried out in Quebec.

Alouette

On the initiative of the Société générale de financement du Québec, an international consortium was created in 1987, to construct a new aluminium smelter in the province. On September 1, 1989, the consortium announced the construction of the Alouette smelter in Pointe-Noire, near Sept-Îles.

By June 1992, Phase I of the aluminium smelter was in full operation. It produces 215,000 metric tonnes of aluminium each year.

Another plant, the Lauralco smelter owned by Alumax, started operations in Deschambault in the Quebec City region. With a capacity of 215,000 metric tonnes a year, it reached full operation in 1993.

Alcoa

At the end of the 20th century, Alcan, which dominated production in Quebec, was joined by its ancestor, Alcoa, who had built the very first smelter in the province.

In July, 1998, Alcoa purchased the Alumax smelter in Deschambault, as well as the 25% share that Alumax held in the Bécancour smelter.

Two years later, Alcoa acquired the Canadian Reynolds Metal Company which also owned the Baie-Comeau smelter, the Bécancour rod plant (Reybec Bécancour) and Reynolds’ food and consumer product packaging as well as Reynolds’ 50% share in the Bécancour smelter.

By 2000, Alcoa owned 75% of the Bécancour smelter, with the other 25% held by the French company, Pechiney.

1998-2004

Development and consolidation

Between 1998 and 2001, Saguenay—Lac-Saint-Jean became the largest construction site in North America, as Alcan undertook the $3 billion construction of a smelter in Alma with an annual production capacity of 400,000 metric tonnes.

In 2000, with the merger of Alcan and the Swiss company Algroup, creating a more vertically integrated operation, Alcan became the world leader in rolled products and the second largest primary aluminium production company.

Two years later, Alouette began its project to expand its smelter in Sept-Îles to increase its annual production capacity from 240,000 to 575,000 metric tonnes.

The first voluntary GHG reduction agreement was signed between the AAC, the Government of Quebec and Alcan, Alcoa, and Alouette (2002-2007).

In 2004, Alcan became the aluminium industry world leader by acquiring Pechiney. At the same time, the company obtained Pechiney’s share in the Bécancour smelter.

2005

Expansion of the Alouette smelter

In January 2005, Alouette started up its new series of 330 cells, increasing annual production to 575,000 tonnes. The aluminium smelter would become the largest in the Americas and the fifth largest in the world. In all, the Alouette expansion project represented an investment of $1.4 billion.

A few months later, the Alouette smelter announced that it would ship half its annual production by water. The “blue highway”, between Sept-Îles and Trois-Rivières, would reduce the number of truckloads on highway 138 by 15,000 each year.

2006-2007

More plant upgrades

In August 2006, Alcan unveiled a plan to upgrade its aluminium smelter in Kitimat, British Columbia; an investment of $1.8 billion.

At the same time, Aluminerie Alouette improved its performance, becoming world leader in energy efficiency for its electrolysis cells.

2007

Major changes at Alcan

On July 12, British-Australian mining giant Rio Tinto made a registered offer for Alcan valued at US$40 billion. This deal did not constitute a merger of two equals, but a takeover of Alcan by Rio Tinto.

On July 17, Rio Tinto and Alcan confirmed the sale of Alcan’s Packaging division as well as the possible sale of other divisions.

In October 2007, Rio Tinto’s purchase of Alcan became official. Rio Tinto agreed to respect all contracts and agreements concluded by Alcan and to make Montréal the world centre of its primary metal division activities. Alcan was integrated to Rio Tinto and formed Rio Tinto.

2008

Start of aluminium crisis

In 2008, the start of the worst recession since the last world war made the price of aluminium—and that of other base metals—plunge in a few months from US$3,000 per metric tonne to less than US$1,300. The slowdown of European and North American economies, which were the main reference markets outside of China, affected demand; 40% of global primary production capacity was running at a loss.

The second voluntary GHG reduction agreement of the primary industry was signed in Quebec (2008-2012).

2009

Upgrades and expansions

The Canadian aluminium industry has progressively been closing the older smelters using Söderberg cells. These are being replaced with plants using prebaked-anode cells with more modern and less emitting technologies.

The Beauharnois smelter was closed in 2009. One of Alcoa’s Baie-Comeau smelter’s potlines has also been shut down and will be replaced with prebaked cells.

Rio Tinto announces the first phase of the AP60 plant – the latest generation of its benchmark AP technology – which will have 38 pots and an annual production capacity of 60,000 tonnes of aluminium. The AP60 technology has 40% higher metal output while being the most environment-friendly technology available on the market.

Renewed industry commitment towards processing in Quebec and the creation of wealth

The primary aluminium production industry, through the Aluminium Association of Canada, was a catalyst of processing in Quebec thanks to its relationship with the province’s government and its society in general.

This commitment resulted in an industrial aluminium cluster and a series of joint initiatives to develop knowledge, usage, and development of Quebec’s aluminium.

Key sectors include public transit, in terms of transportation electrification, buildings, infrastructure, and bridges. As aluminium processing has yet to reach its full potential in Quebec, several steps must be taken to properly position this industry, namely the development of Canadian standards, the dissemination of training content, and the production of relevant guidelines and studies.

2010

Publication of the first report on sustainable development

The AAC published its first report on sustainable development of the Canadian primary aluminium industry.

2011

Rio Tinto announces investment

Rio Tinto announced an additional major investment to further upgrade the Kitimat smelter.

2013

Creation of AluQuébec

The Quebec Aluminium Cluster was founded, operating as AluQuébec.

Rio Tinto and Alcoa’s last two Söderberg cells in Quebec were decommissioned at the Shawinigan and Baie-Comeau facilities.

Aluminium production in the Shawinigan region ceased after more than 100 years of activity.

The aluminium industry is considered to be a large GHG emitter and is subject to the cap-and-trade system for greenhouse gas emission allowances in effect.

First metal produced from cells at Rio Tinto’s Arvida AP60 Technology Centre.

2014

Alcoa renews contracts for three plants

Alcoa renewed contracts for energy blocks at its Baie-Comeau, Deschambault, and Bécancour smelters.

Quebec linked its carbon market system with California’s; the first joint auctions were held.

In the wake of commitments announced during Premier Couillard’s throne speech, the Quebec government launched work on the Quebec Aluminium Development Strategy.

The first Canadian International Aluminium Conference (CIAC) was held in Montréal.

2015

Québec’s Aluminium Development Strategy

The government of Quebec announced the launch of the Québec Aluminium Development Strategy 2015-2025. $32.5 million will be injected into implementing the strategy over the first three years. As such, Quebec is giving itself the means to promote the growth and enhancement of the entire aluminium value chain.

2016

In April, the United Steelworkers (USW) files a petition to impose a 50% tariff on aluminium imports from Canada to the U.S. This appeal was withdrawn a few days later.

In September, the AAC pleads for a fair competition before a US Congressional Committee (USITC) to identify global competitive conditions for the industry.

2017

Historic production milestone for Aluminerie Alouette

On June 27, Aluminerie Alouette reaches 10 million tons of aluminium produced in 25 years - a historical milestone for the largest aluminium smelter in the Americas and its employees.

2018

U.S. Tariffs on Canadian Aluminium and Montreal Aluminium Summit

In February, Rio Tinto announces a C$250 million investment and extended the life of its Vaudreuil alumina refinery located at the Jonquière Complex, Quebec, Canada.

On May 31, the United States imposes a 10% tariff on Canada and Mexico on aluminium imports and 25% on steel.

Montreal Aluminium Summit is held in June to develop an Action Plan for a Global Governmental and Multilateral Forum on Aluminium Industry Overcapacity to be conveyed to G7 and G20 representatives.

On June 21, ELYSIS, a joint venture between Alcoa and Rio Tinto, with the support of the Government of Quebec, the Government of Canada and Apple, is created to commercialize an innovative and revolutionary technology for the aluminium industry. This technology will optimize production and eliminate all greenhouse gas emissions related to the production of primary aluminium by electrolysis. The only output from this new process will be oxygen.

In 2018, Rio Tinto becomes the first company to receive the Aluminium Stewardship Initiative (ASI) certification for “responsible” aluminium production in Canada.

2019

Lifting of American tariffs and signing of the new CUSMA

In May, an agreement is signed between Canada and the United States that leads to the lifting of tariffs on Canadian aluminium and steel.

On July 5, Rio Tinto announces an investment of $209 million in its Alma facility to increase its aluminium production capacity, a project that had been put on hold due to the tariffs. Aluminerie Alouette is launching a $474 million investment program to make the technological transition of its facilities. Of this amount, $15 million will come from the federal government’s Strategic Innovation Fund. This major investment will allow for the transition to liquefied natural gas, the robotization of certain facilities and the introduction of remotely operated vehicles in the aluminium smelter.

On June 19, Alcoa announces an investment of $85 million to increase production at the Deschambault smelter while maintaining its environmental performance. The federal government also announces $10 million in assistance.

On August 16, ELYSIS officially launches the construction of its Research and Development Center in Saguenay.

On August 23, aluminium is added to the Government of Canada’s Import Control List to prevent dumping, transshipment and import surges.

December 10, signing of the new Canada-US-Mexico Free Trade Agreement (CUSMA).

2020

COVID-19, US tariffs and traceability

On January 13, Aluminerie Alouette breaks its all-time record of producing over 620,000 tonnes of aluminium in 2020.

On January 28, AAFC announces the successful completion of the initial phase of the strategic aluminium traceability project in Canada, a first worldwide.

On March 3, Rio Tinto announces the launch of START, the first sustainability label for aluminium.

In February and March, Rio Tinto announces a C$105 million investment to upgrade its Port-Alfred port facilities in Saguenay, Quebec to improve safety and operational efficiency, and an additional $92 million investment in its IsleMaligne power plant for replacement and refurbishment work to improve the reliability of its hydroelectric power plant. Located in Alma, the plant was commissioned 95 years ago and is the oldest in Rio Tinto’s hydroelectric system.

On March 11, Natural Resources Canada announces that aluminium is on the Government of Canada’s list of 31 critical minerals for the long-term economic prosperity of Canada and its allies.

On June 29, the Government of Canada announces an additional $20 million investment in the ELYSIS project.

On September 2, Alcoa announces that its Deschambault and Bécancour aluminium smelters (ABI) have achieved Aluminium Stewardship Initiative (ASI) performance standard certification, the industry’s most comprehensive system for third-party validation of sustainable manufacturing processes. All three aluminium smelters Alcoa operates in Canada are ASI-certified, with the Baie Comeau smelter being certified in 2019.

On November 4, ELYSIS reaches another milestone and successfully produces aluminium with no direct greenhouse gas emissions at its Saguenay Industrial Research and Development Centre.

On November 16, the Quebec government unveiled the renewal of its 2021-2024 Quebec Aluminium Strategy with a $475 million funding to strengthen the industry’s competitiveness.

On November 17, Rio Tinto announces an investment of US$87 million to increase its production of low-carbon aluminium in Canada with 16 new pots at its AP60 smelter in the Saguenay region of Quebec.

In November 2021, ELYSIS successfully produced aluminium with no direct greenhouse gas emissions at its research and development center using a complete industrial concept comparable in size to the small smelters in use in the industry today.

2021

Traceability, critical minerals and SQDA renewal

On January 13, Aluminerie Alouette breaks its all-time record of producing over 620,000 tonnes of aluminium in 2020.

On January 28, AAFC announces the successful completion of the initial phase of the strategic aluminium traceability project in Canada, a first worldwide.

On March 3, Rio Tinto announces the launch of START, the first sustainability label for aluminium.

In February and March, Rio Tinto announces a C$105 million investment to upgrade its Port-Alfred port facilities in Saguenay, Quebec to improve safety and operational efficiency, and an additional $92 million investment in its IsleMaligne power plant for replacement and refurbishment work to improve the reliability of its hydroelectric power plant. Located in Alma, the plant was commissioned 95 years ago and is the oldest in Rio Tinto’s hydroelectric system.

On March 11, Natural Resources Canada announces that aluminium is on the Government of Canada’s list of 31 critical minerals for the long-term economic prosperity of Canada and its allies.

On June 29, the Government of Canada announces an additional $20 million investment in the ELYSIS project.

On September 2, Alcoa announces that its Deschambault and Bécancour aluminium smelters (ABI) have achieved Aluminium Stewardship Initiative (ASI) performance standard certification, the industry’s most comprehensive system for third-party validation of sustainable manufacturing processes. All three aluminium smelters Alcoa operates in Canada are ASI-certified, with the Baie Comeau smelter being certified in 2019.

On November 4, ELYSIS reaches another milestone and successfully produces aluminium with no direct greenhouse gas emissions at its Saguenay Industrial Research and Development Centre.

On November 16, the Quebec government unveiled the renewal of its 2021-2024 Quebec Aluminium Strategy (SQDA) with a $475 million funding to strengthen the industry’s competitiveness.

On November 17, Rio Tinto announces an investment of US$87 million to increase its production of low-carbon aluminium in Canada with 16 new pots at its AP60 smelter in the Saguenay region of Quebec.

In November 2021, ELYSIS successfully produced aluminium with no direct greenhouse gas emissions at its research and development center using a complete industrial concept comparable in size to the small smelters in use in the industry today.

2022

On February 2, Aluminerie Alouette celebrates its 30th anniversary of operation and a record production year.

On June 22, Aluminerie Alouette announces the successful implementation of the conversion of its anode baking furnaces from oil to natural gas, an overall investment of more than $23 million. The project was announced in October 2020. This project was made possible through a partnership with the Quebec Ministry of Energy and Natural Resources and Energir.

On June 29, Rio Tinto, in partnership with Corona Canada, announces the launch of the first low-carbon, branded beverage can in Canada, manufactured by Ball Corporation. The cans, available on a pilot basis in Ontario, are made from Rio Tinto aluminium and feature ELYSIS technology. For this limited launch, 1.2 million cans were tagged with a QR code to encourage consumers to learn more about their low carbon footprint. This pilot test is a first step toward bringing a fully traceable beverage can to market.

July 13, Rio Tinto announces a C$240 million investment to increase low-carbon, high-value aluminium billet production capacity by 202,000 metric tonnes at its Alma smelter in Lac-Saint-Jean, Quebec.

On August 26, 2022, Rio Tinto announces a C$35 million investment to establish a new aluminium recycling facility at its Arvida smelter in Saguenay–Lac-Saint-Jean, Quebec to expand its offering of low-carbon aluminium solutions for customers in the automotive, packaging and construction markets. Rio Tinto becomes the first primary aluminium producer in North America to integrate post-consumer recycled aluminium into aluminium alloys.

On October 19, 2022, Aluminerie Alouette announced that it had achieved certification to the ASI Chain of Custody Standard (production, maintenance and service operations related to aluminium manufacturing). It was first certified in July 2020 to the ASI Performance Standard, which defines environmental, societal and governance principles and criteria to address sustainability issues in the aluminium value chain.